We begin by conducting a vehicle audit at the time the car arrives in our plant. It is checked for functional, originality and physical integrity. The entire process is documented and a report is generated as a result of this inspection.

Vehicle is methodically taken apart, and each part, set of screws and bolts labeled and classified in its storage (locked) cage. The entire process is photographed for future reference.

Car is taken through a process that entails applying a chemical paint remover, followed by a soda blasting to reveal the metal condition of the entire car. The entire car is brought to the bare metal.

At this stage a coat of clear prime is applied throughout the entire car to ensure that the bare metal does not get exposed to the elements that result in rusting. This primer enables clear visibility of the state of sheet metal so that areas affected are exposed and can be worked on.

All vehicle parts (power train, radiator, fuel pump, gas tank, etc.) are inspected for condition, media blasted, rust treated, resealed, repaired, primed and painted in the factory finish.

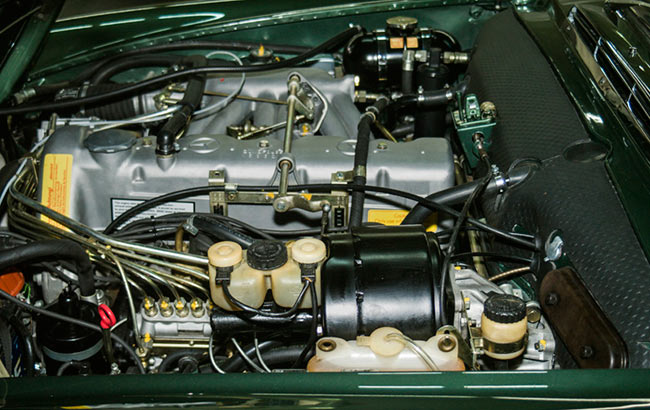

The engine and other critical mechanical parts, such as fuel pumps, transmissions, etc. are rebuilt. Fuel injection pumps are sent out to H&R Fuel Injection for restoration. All engines are rebuilt using original Mercedes-Benz parts to factory specifications. Engines are extensively bench tested prior to mounting on the car.

This stage entails correcting all sheet-metal on the car – both structural, as well as body. This process entails replacement of floors, and other parts, as may be necessary. Careful attention to detail is required to maintain original spot welds and other factory welds, etc. We make extensive use of Led in areas where deemed necessary.

The car is taken through a rust treatment process, which cures any areas that have been affected by rust through the years. Sheet-metal is repaired & welded where necessary, and POR15 rust treatment is also applied in areas that commonly rust to ensure that it does not surface in the future.

This entails preparing the body of the car prior to the paint process, ensuring that little to no bondo is applied to the car. Several stages of primer and block sanding are carried out during this stage. A coat of primer filler is also applied to the car during this phase of the work. All primer products applied to the car are Glassurit products.

A much more detailed body preparation process is undertaken at this stage preparing the car for the paint process. A primer sealer is applied and the body wet block sanded with 800 to 1200 grit sand paper. Detailed corrections made to ensure a perfectly smooth surface prior to entering the paint booth. This stage may take as long as a week or two to achieve a perfect body ready for the paint booth. every gap on every part of the car is measured carefully prior to paint.

This phase entails a multi-stage process, in which the application of an under-body original Shutz material; painting of the under-body, trunk and engine compartment in its original factory finish; as well as painting the body cabin. The final paint is sprayed after the chrome has been fitted onto the car. The only paint and clear product used on the vehicles is BASF Glassurit factory paint (primer, base & clear).

At this stage the Wood and Upholstery are completed for fitting on the vehicle. The chrome has been copper plated and fitted on the car prior to painting, and is now all completed for installation. All done inhouse to ensure the best fit possible.

Car is meticulously assembled to ensure the proper fit of every component. An assembly process well done shows off a finely done restoration. Conversely, an improper assembly may destroy an otherwise fine job. Attention to details is critical at this stage.

The car is submitted to a number of tests in the plant, and then finally driven for break-in and final adjustments. The car is driven in different conditions, and different speeds to ensure its proper operation. Likewise, every function of the car is tested to validate proper functionality. Many adjustments and fine-tuning are performed during this phase.

After extensive road testing, that includes driving the car on the highway several times; the car is then fully detailed and a final inspection is made to ensure that everything is in order prior to strapping in a container for shipment.